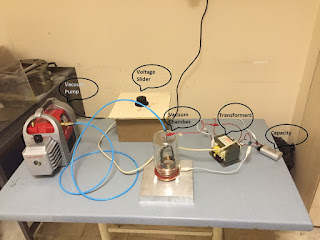

This pictures are our design and first prototype.

DC Magnetron Sputtering Machine

3 Ocak 2016 Pazar

24 Ekim 2015 Cumartesi

Definitons of the DC Magnetron Subcomponents

What is the Plasma ?

Plasma is considered the fourth state of matter. The three other states are solid, liquid, and gas. Plasma is a cloud of protons, neutrons and electrons where all the electrons have come loose from their respective molecules and atoms, giving the plasma the ability to act as a whole rather than as a bunch of atoms. A plasma is more like a gas than any of the other states of matter because the atoms are not in constant contact with each other, but it behaves differently from a gas. It has what scientists call collective behavior. This means that the plasma can flow like a liquid or it can contain areas that are like clumps of atoms sticking together.

What is an ion ?

An ion is a charged atom or molecule. It is charged because the number of electrons do not equal the number of protons in the atom or molecule. An atom can acquire a positive charge or a negative charge depending on whether the number of electrons in an atom is greater or less then the number of protons in the atom.

When an atom is attracted to another atom because it has an unequal number of electrons and protons, the atom is called an ION. If the atom has more electrons than protons, it is a negative ion, or ANION. If it has more protons than electrons,it is a positive ion.

What is a cathode and anode ?

A 'Cathode' is a Negatively charged Electrode that attracts the Positive ions in a Circuit or Chemical reaction.

Plasma is considered the fourth state of matter. The three other states are solid, liquid, and gas. Plasma is a cloud of protons, neutrons and electrons where all the electrons have come loose from their respective molecules and atoms, giving the plasma the ability to act as a whole rather than as a bunch of atoms. A plasma is more like a gas than any of the other states of matter because the atoms are not in constant contact with each other, but it behaves differently from a gas. It has what scientists call collective behavior. This means that the plasma can flow like a liquid or it can contain areas that are like clumps of atoms sticking together.

What is an ion ?

An ion is a charged atom or molecule. It is charged because the number of electrons do not equal the number of protons in the atom or molecule. An atom can acquire a positive charge or a negative charge depending on whether the number of electrons in an atom is greater or less then the number of protons in the atom.

When an atom is attracted to another atom because it has an unequal number of electrons and protons, the atom is called an ION. If the atom has more electrons than protons, it is a negative ion, or ANION. If it has more protons than electrons,it is a positive ion.

What is a cathode and anode ?

A 'Cathode' is a Negatively charged Electrode that attracts the Positive ions in a Circuit or Chemical reaction.

The 'Anode' is the Positively charged Electrode that attracts the Negative ions (Anions) in a Circuit or Chemical reaction.

References: http://www.wisegeek.org/what-is-a-magnetron.htm

http://www.qrg.northwestern.edu/projects/vss/docs/propulsion/2-what-is-plasma.html

What is the DC Magnetron Sputtering ?

DC (direct current) sputtering is a material deposition process used to coat substrate structures with thin films of different materials. The process involves bombarding a donor material with ionized gas molecules, causing a displacement of donor atoms. These atoms then adhere to a negatively charged recipient material creating a thin film on its surface. This technique is used extensively in the electronics industry to construct semiconductor components and printed circuit boards (PCBs). It may, however, be appropriate for many other applications, such as non-reflective coatings on glass optic elements, metalized packaging plastics, and double glazing coatings.

The application of very thin layers or films of material on sensitive surfaces is generally achieved by a sputtering processes. This type of material deposition is achieved by passing a high tension electric current through an inert, low pressure gas, such as argon, which surrounds a donor and recipient material. The high energy plasma created causes rapidly accelerated ions to strike the donor material, displacing its atoms. The donor atoms then strike and adhere to the target or recipient material at an atomic level and create a very thin, even film. DC sputtering is capable of extremely accurate and controllable material deposition on a wide variety of substrate surfaces.

Reference: http://www.wisegeek.org/what-is-dc-sputtering.htm

Kaydol:

Yorumlar (Atom)